- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Parallel Beam X Ray Diffraction Analysis

Some of the major drawbacks of traditional XRD are that it is often based on bulky equipment with high power requirements. Furthermore, most conventional instruments use a parafocusing Bragg-Brentano geometry, offering the advantages of high-resolution and high beam-intensity analysis at the cost of very precise alignment requirements and carefully prepared samples. Additionally, this geometry requires that the source-to-sample distance be constant and equal to the sample-to-detector distance. Ensuing errors often lead to difficulties in phase identification and improper quantification. A mis-positioned sample, a partially transparent sample, or a rough sample can lead to unacceptable specimen displacement errors. The sample flatness, roughness, and positioning constraints usually preclude in-line measurements. These constraints are removed if the incident X-ray beam is parallel.

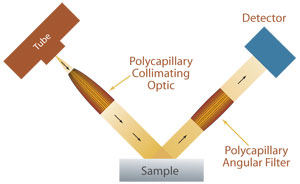

In parallel beam x ray diffraction analysis, a polycapillary collimating optic can be used to form an intense parallel X-ray excitation beam resulting in very high X-ray intensities at the sample surface. The definition of x-ray diffraction is

With parallel-beam geometry, the sample position can vary and the XRD system is no longer constrained to maintain the same distance between the X-ray source and sample as between the sample and detector. The geometric flexibility can accommodate existing manufacturing conditions and can be used on a much broader range of sample shapes and sizes. Parallel beam XRD is not only insensitive to errors associated with sample displacement; it virtually eliminates all of the other well-known instrument error functions, which contribute to asymmetric peak broadening, such as non-flat or rough specimens, axial divergence, and sample transparency. As a result, minimal sample preparation is required. Furthermore, through use of a polycapillary collimating optic, the target parallel beam XRD system can be combined with a low power X-ray source, reducing instrument size and power requirements. Parallel beam XRD using X-ray optics has been successfully used for applications including thin film analysis, sample texture evaluation, monitoring of crystalline phase and structure, and investigation of sample stress and strain.

The elimination of multiple sources of error and the potential for reducing the power, size, weight, and cost of an instrument makes parallel beam X-ray systems natural candidates for on-line diffraction systems for quality control and feedback in manufacturing and process environments. Parallel-beam XRD has been successfully used in process applications for phase distribution measurements in the pharmaceutical and steel industries, thin film texture measurements for superconductor layers and magnetic films, and structure measurements for proteins.