- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Parallel Beam X-Ray Diffraction Techniques for Texture Measurements

Texture measurements are used to determine the orientation distribution of crystalline grains in a polycrystalline sample. A material is considered “textured” if the grains are aligned in a preferred orientation along certain lattice planes. One can view the textured state of a material (typically in the form of thin films) as an intermediate state, with properties between a randomly oriented polycrystalline powder and a completely oriented single crystal. Texture is usually introduced in the fabrication process of a material (e.g. rolling of thin sheet metal, deposition,etc.), which can affect the material properties by introducing structural anisotropy.

Preferred crystallographic orientation or texture is present in most crystals as a result of mechanical or thermal treatment and therefore it is process dependent. The texture of these materials may strongly affect their properties. Consequently, it is necessary to quantify these effects in order to optimize the development, processing, and application of textured materials. Relative intensities of diffraction peaks in a conventional XRD scan are used as preliminary indications of crystal texture. A peak that is stronger than all other peaks from a random specimen identifies a direction of preferred crystallographic orientation that is normal to the diffracting planes for the peak. The degree of texture is indicated by the full width at half maximum (FWHM) of the peak.

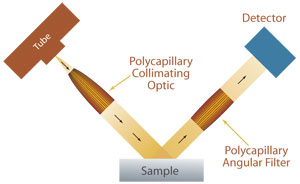

Parallel beam X ray Diffraction Techniques using polycapillary collimating optics can be used to enhance texture analysis of materials. Due to the insensitivity of parallel beam XRD to sample geometry and displacement errors, minimal sample preparation is required for texture analysis of samples. For the same reasons, the technique can be used to monitor on-line changes in a material. Furthermore, through use of a polycapillary collimating optics, the parallel beam XRD system can be combined with a low power x-ray source, reducing instrument size and power requirements for in-line texture measurements.

Parallel Beam X-ray Diffraction geometry using polycapillary collimating optics. This technique has been successfully used for thin film texture measurements for quality control of superconductor tape layers and the manufacturing of magnetic films.