- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Optimize Workflow with the Sindie Series

BACKGROUND

XOS’ Sindie® series sulfur analyzers offer a variety of features and capabilities aiming to improve your operational efficiencies. In addition, XOS’ applications scientists have worked with a wide range of customers to develop best practices and techniques that can further reduce measurement and calibration times while maintaining and improving precision and method compliance.

XOS’ Sindie 2622 is renowned for its precision, accuracy, and ease of use. This analyzer is available in a variety of configurations, such as Sindie 2622 Generation (Gen) 3, which has higher-performing optics and superior analytical performance in addition to a lower limit of detection (LOD) and better precision at low sulfur levels. It also offers significant time-saving capabilities, including enhanced optics to reduce background measurement time in 2622 measurement mode and the use of preassembled Accucell sample cups.

CHALLENGE

Regardless of the instrument used, ASTM D2622 first requires that a background measurement be taken, followed by the sample measurement. When run in 2622 mode, Sindie 2622 performs a background measurement automatically—a feat accomplished through slight movement of the sample during the measurement. Per method requirements, the background measurement is taken first, followed by the sample cup being lowered into the basket for sulfur measurement. The analyzer automatically subtracts the background measurement from the sulfur measurement, providing the net sulfur concentration of the sample.

Sindie 2622 Gen 2, when run in 2622 mode, requires the background measurement time to be equal to the sample measurement time. During the standard 300-second sulfur measurement time, an additional 300 seconds of background measurement time is required, for a total cycle time of 600 seconds per sample. Because ASTM D2622 requires duplicate measurements for samples with less than 100 ppm sulfur, the resultant total time to measure a typical finished product sample is 1200 seconds (20 minutes).

ACCUCELL SAMPLE CUPS

Accucells are essentially smaller, pre-assembled standard XRF sample cups. The sample is inserted through a hole on top of the cup. These sample cups are pre-vented, so there is no need to punch vent holes.

SOLUTION

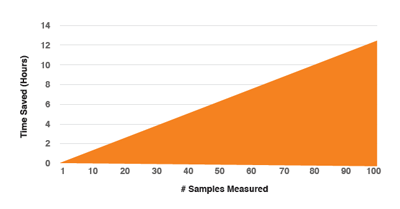

In comparison to Sindie 2622 Gen 2, Sindie 2622 Gen 3 offers a time-saving solution which reduces total cycle time in 2622 mode by 38%, or more than 7 minutes per sample. This is because Sindie 2622 Gen 3 has advanced optics and newly-updated software that allow the background measurement time to be reduced to only 20% of the total measurement time, with complete compliance with ASTM D2622 and no detrimental impact on analytical performance. For a typical 300-second sample measurement time, the background time can be reduced from 300 seconds to only 75 seconds. The resultant 375-second measurement time on Sindie 2622 Gen 3 is 225 seconds shorter than on Sindie 2622 Gen 2 – a 38% reduction. For samples below 100 ppm that require duplicate measurements, this feature results in a time savings of more than 7 minutes per sample! For a typical lab running 10 to 25 samples daily, this is a time savings of 1 to 3 hours per day, or 15 to 45 hours per week – while maintaining full compliance with ASTM D2622 and with no negative impact on precision or accuracy.

Utilizing Sindie 2622 Gen 3 with XOS’ preassembled Accucell sample cups, regardless of running in 7039 or 2622 mode, provides additional time-savings. These preassembled cups only need for the operator to pipette about 1 ml of sample into the measurement cup without needing to fumble with cup rings or sample film. The several seconds saved per sample may not seem like much, but over the course of a day or a week in a standard lab, this can result in significant time savings. With standard sample cups, even the best of operators will occasionally have cases where the ring does not seat properly on the cup, resulting in the waste of consumables and samples, as well as time, as they must start over. If not noticed, improper seating of the ring will also often result in leakage of the sample onto the instrument, leading to additional time lost to stop and clean up the analyzer. This, in turn, increases the chances of cross contamination of samples.

CONCLUSION

Sindie 2622 Gen 3 offers a time-saving solution with the option to reduce the background measurement time to 20% of the total measurement time. Compared to Sindie 2622 Gen 2, Sindie 2622 Gen 3 offers:

- Reduced background measurement time in 2622 mode (shown in Figure 1), reducing cycle time by almost 4 minutes per single measurement and more than 7 minutes per sample for duplicate D2622 samples.

- Use of preassembled Accucell sample cups, saving time and waste in addition to minimizing risk of contamination.

Figure 1: Saved Time with Sindie 2622 Gen 3

MORE ABOUT THE SINDIE SERIES

The entire Sindie 2622 product line offers several features, add-ons, and capabilities that further enhance the efficiency of your lab, including:

- Eliminating need for background measurement time by utilizing 7039 mode

- Eliminating need for duplicate measurements for samples ≤100 ppm by utilizing 7039 mode

- Saving time by preloading up to eight samples into the Sindie autosampler add-on feature

- Improving operational efficiencies by following the best practices developed through years of experience by the XOS Applications Team

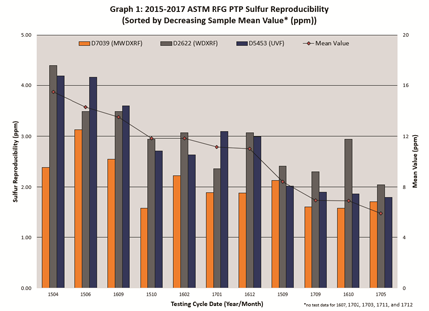

In addition to the enhanced X-ray optics and software that allow for a reduction in background measurement time in 2622 mode, all Sindie 2622 analyzers also offer a feature that allows the instrument to run in 7039 mode. ASTM D7039 is a more recent sulfur method that better represents the most current XRF technology. ASTM D7039 is a well-established method that provides equal, if not better* (see Figure 2 comparing real-world precision between D7039, D2622 and D5453) precision than ASTM D2622 for low levels of sulfur in hydrocarbons.

Figure 2: PTP Graph

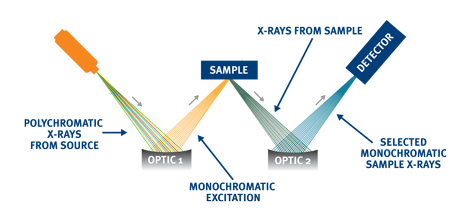

Unlike ASTM D2622, ASTM D7039 does not require a background measurement cycle. This is because when ASTM D7039 was developed, X-ray Fluorescence (XRF) technology had advanced to the point where background measurements were no longer needed to provide high precision at low sulfur levels through the use of a monochromating excitation optic. ASTM D7039 makes use of a newer technology: Monochromatic Wavelength Dispersive XRF (MWDXRF), which provides a lower signal-to-background ratio, meaning background measurement is not necessary to achieve high precision at very low sulfur levels. The filtering and focusing capability of the excitation optic means that the background noise is removed from the incident X-rays prior to sample excitation, which results in a daily time savings that ultimately amounts to several hours per week.

Read our Precision Comparison Between ASTM Test Methods D7039, D2622 and D5453 whitepaper to learn which method demonstrates the best performance for reproducibility at xos.com/precision-compare.

ASTM D7039 does not require duplicate measurements on samples. This, combined with being able to measure without background measurement, results in a time savings of up to 15 minutes per sample (for ≤100 ppm samples). Over the course of a week in a typical lab, this reduces the time needed to measure samples by 10 to 25 hours per week.

AUTOSAMPLER

The autosampler, an optional feature, increases productivity by utilizing its eight-sample cell capacity.

While the autosampler feature is not an available option for Sindie 2622 Gen 3, Sindie 2622 Gen 2 still offers the time-saving benefits of using preassembled Accucell sample cups and running in 7039 mode (no background or duplicate measurement required). The optional eight-sample autosampler feature adds additional operational efficiencies, allowing operators to preload up to eight samples, set up the measurements, and initiate those measurements. The analyzer will then cycle through all of the samples automatically, allowing the operator to perform other tasks while the samples are running.

CALIBRATION AND MAINTENANCE

Proper use, calibration, and maintenance of your Sindie analyzer can go a long way towards saving time and money over the life of the instrument. The XOS Applications and Service teams have worked with customers around the world to develop a set of best practices and tips to not only ensure the highest precision and accuracy of your results, but to also save you time day-in and day-out.

By following the best practices developed by years of experience, you will save a significant amount of time by “getting it right the first time”. Use of the proper procedures will reduce incorrect or questionable results, improving performance and efficiency.

A good calibration is essential to minimize systematic error, improve results, and save time, so be sure to follow these steps to obtain a good Sindie D2622 calibration:

- Have a good calibration blank, as a bad blank will lead to a high calibration intercept and poor accuracy at the lower end of the calibration range

- Use a new sample aliquot for duplicate measurements (per D2622 methodology)

- Auto-calibration is recommended to obtain a weighted-least squares calibration

- Do not tightly bracket the calibration range

Sindie users commonly follow good calibration practices, but many do not understand how weighted-least squares work and why tightly bracketing the calibration range is discouraged. Sindie uses MWDXRF spectrometry for analysis whether in D7039 or D2622 measurement mode, and the MWDXRF X-ray counting statistics are governed by the Poisson distribution. As a result, the standard deviation on any total number of counts, X, is the square root of the counts, X0.5 concentration in ppm.

The square root function is also used for the Sindie autocalibration model (known as linear weighted-least squares). This model assumes a square root relationship between the data value and its error. This means that the model takes into account that the error is not the same on every calibration point, whereas the normal least-squares (non-weighted) linear function assumes the same error for every data point regardless of concentration. The non-weighted calibration function does not consider the better absolute precision of the low concentration data and is therefore over-influenced by high concentration data. To combat this, the calibration range of a non-weighted calibration is traditionally tightly bracketed around the range of interest. This also means that multiple non-weighted calibration curves are needed to cover a larger range of interest. In contrast, the weighted linear model can cover a larger concentration range with one calibration, because higher concentration points do not have this negative effect on the calibration. Moreover, the higher concentration points serve an additional function, which is perhaps more important in this particular application, because the weighted least squares produce a calibration intercept with a lower standard error than that of a non-weighted calibration.

In short, these higher calibration points allow the user to take advantage of the better absolute precision at the lower end of the concentration range. Essentially, these higher concentration calibration points, which are usually well above the typical range of interest, will improve the overall calibration in the lower range of interest. Therefore, even though the typical range of interest may be 0-10 ppm, it is recommended to calibrate the Sindie analyzer 0-500 ppm, or even 0-3000 ppm if measuring higher than 500 ppm.

Cleanliness

A clean sample preparation area will ensure there is no cross-contamination among samples. It is entirely possible that an XRF cup, for example, coming into contact with a used pipette containing another sample type, could have an impact on data integrity. For best results, keep the preparation area clean by following these recommended precautions:

- Keep all materials, such as XRF cups and pipettes, in sealed rather than open containers

- Conduct all sample preparation under a vented hood

- Keep sample film box closed when not in use

In addition to cleaning the sample preparation area, it is especially important to maintain a clean analyzer as well. As multiple samples are run in an analyzer, occasional leaks can build up and become data liabilities. For best results, the following tasks should be performed daily to ensure your XRF analyzer does not introduce risk to your data:

- Clean the sample plunger and sample basket using isopropyl alcohol (IPA) and a lint-free cloth

- Be sure to regularly check and replace your secondary window

- Carefully clean the primary window using IPA and a foamtipped swab (make sure you have a spare primary window before instituting a regular cleaning procedure)

Finally, an instrument that is well-maintained will always provide the highest degree of efficiency and reliability, minimizing chances for poor results and rework, among other inconveniences. XOS offers a range of service packages that can keep your instrument running at its best. Please contact support@xos.com for more information.

Read our Best Practices for Improve Sulfur Repeatability whitepaper at xos.com/bestpractices to learn more.

Sindie Series Wrap Up

The Sindie Series can save your lab significant time throughout a typical workday by:

- Operating in 7039 mode, saving 5 to 15 minutes per sample vs running in 2622 mode, as neither background measurement nor duplicate measurements for samples below 100ppm are required

- Preloading up to eight samples in the optional Sindie autosampler add-on, freeing up a significant amount of time for the operator during measurement

- Providing an accurate measurement combined with good analyzer precision and calibration techniques will help to ensure quality results

Sindie 2622 Gen 3

Sindie 2622 Gen 3 complies with ASTM D2622, ASTM D7039 and ISO 20884 methods, enabling complete flexibility in sulfur analysis. With no compromises in detection, performance, or reliability, Sindie 2622 is the ideal sulfur analytical solution from ultra-low sulfur diesel and gasoline to heavy fuel oil and crudes.

MWDXRF (Monochromatic Wavelength Dispersive X-ray Fluorescence)

MWDXRF® utilizes state-of-the-art focusing and monochromating optics to increase excitation intensity and dramatically improve signal-to-background over traditional high-power WDXRF instruments. This enables significantly improved detection limits and precision, and a reduced sensitivity to matrix effects. A monochromatic and focused primary beam excites the sample, and secondary characteristic fluorescence X-rays are emitted from the sample. A second monochromating optic selects the sulfur characteristic X-rays and directs these X-rays to the detector. MWDXRF is a direct measurement technique and does not require consumable gasses or sample conversion.

Author: Satbir Nayar, Sr. Product Manager