- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Simple Lubricant Additive Package Quality Control Using HDXRF®

BACKGROUND

Professionals in the field of lubrication and tribology are at the forefront of solving many of today's biggest problems. Long recognized for their contributions ensuring safe, reliable, and continuous operation of the most complex machine systems, lubrication and tribology is now a major contributor to reduction in energy use, minimizing maintenance and repairs of equipment, and conservation of natural resources. The Society of Tribologists and Lubrication Engineers (STLE), one of the largest professional societies in the field, estimates that global economies save hundreds of billions of dollars per year with proper application of the science and research being advanced by thousands of professionals around the world.

CHALLENGE

Lubricants are comprised of base oil and an additive package. The base oil provides a level of lubrication in and of itself, but also serves as a carrier for additives. The additives enhance existing properties of the base oil like viscosity, oxidation resistance, pour point, and viscosity index, as well as providing new properties like anti-wear performance and corrosion control. Additives can make up as much as 30% of the formulated lubricant. The same can be said of greases, which act similarly to lubricants and also contain additive packages. Ensuring that final formulation meets specifications is an important part of quality control. The additive packages mentioned above often contain elements such as phosphorus (P), calcium (Ca), and zinc (Zn). Industry experts have long used a simple analysis technique called X-ray fluorescence (XRF) to measure these elements and ensure that blended lubricants meet the required specifications. In addition, XRF can also measure sulfur and chlorine which may have prescribed levels in the final product. This application note will demonstrate the performance and simplicity of Petra MAX™, powered by HDXRF, to meet the needs of lubricant professionals to perform these essential quality control analyses.

SOLUTION

Petra MAX is an ideal solution for quality control of finished lubricants and base oils, delivering rapid measurement of 13 elements from P to Zn in hydrocarbons, water and catalyst applications. This analyzer complies with ASTM D4294, ISO 8754, and IP 336 standard test methods. It is compact, robust, and easy for non-technical operators to use. Analysis is as simple as pouring a small amount of sample into a disposable plastic cup, sealing with a plastic film, closing the lid on the analyzer and pressing a button.

APPLICATION STUDY

MEASURING LUBRICANT OILS

To demonstrate the capability of Petra MAX to quantify the elemental content of a lubricant additive package, we measured two standards provided by a leading certified reference material supplier with concentrations shown in Table 1. To prepare the samples for measurements, the lubricant oils were transferred from the standard container to an unused, clean polyethylene sample cup and sealed with a 3µm Etnom® film.

| Table 1: Standard Concentrations (ppm) | ||||

|---|---|---|---|---|

| Ca | P | S | Zn | |

| Lubricant 1 | 100 | 1250 | 6000 | 600 |

| Lubricant 2 | 5000 | 300 | 1500 | 700 |

Each standard was measured 10 times to assess the repeatability of the results, which are shown in Tables 2 and 3 respectively. The measurements show a high degree of repeatability, highlighting the precision of the instrument for quantifying typical lubricant package elements in oils, with a bias of 10% or less compared to the reference values from the supplier.

| Table 2: Lubricant Oil Sample 1 (ppm) | ||||

|---|---|---|---|---|

| Scan # | Ca | P | S | Zn |

| 1 | 108 | 1254 | 6090 | 579 |

| 2 | 107 | 1267 | 6110 | 579 |

| 3 | 110 | 1242 | 6110 | 580 |

| 4 | 109 | 1298 | 6130 | 580 |

| 5 | 109 | 1244 | 6060 | 579 |

| 6 | 108 | 1263 | 6120 | 579 |

| 7 | 109 | 1272 | 6100 | 578 |

| 8 | 109 | 1293 | 6120 | 579 |

| 9 | 109 | 1295 | 6090 | 579 |

| 10 | 108 | 1263 | 6140 | 579 |

| Average | 109 | 1269 | 6107 | 579 |

| Standard Deviation | 0.9 | 20.5 | 23.1 | 0.5 |

| Relative Standard Deviation | 0.8% | 1.6% | 0.4% | 0.1% |

| Table 3: Lubricant Oil Sample 2 (ppm) | ||||

|---|---|---|---|---|

| Scan # | Ca | P | S | Zn |

| 1 | 5345 | 357 | 1560 | 681 |

| 2 | 5354 | 375 | 1550 | 682 |

| 3 | 5367 | 379 | 1550 | 684 |

| 4 | 5370 | 335 | 1560 | 684 |

| 5 | 5367 | 334 | 1550 | 684 |

| 6 | 5364 | 329 | 1550 | 684 |

| 7 | 5369 | 350 | 1540 | 684 |

| 8 | 5364 | 319 | 1530 | 684 |

| 9 | 5372 | 308 | 1560 | 683 |

| 10 | 5374 | 352 | 1550 | 683 |

| Average | 5365 | 344 | 1550 | 683 |

| Standard Deviation | 8.7 | 23.1 | 9.4 | 1.1 |

| Relative Standard Deviation | 0.2% | 6.7% | 0.6% | 0.2% |

MEASURING LUBRICANT GREASES

Greases are most commonly used in automotive and household applications in anti-friction. To assess the performance of Petra MAX to test greases for elements such as phosporous and calcium, a standard, low-grade white lithium grease and a higher grade marine calcium grease were both analyzed. Each of these samples were tested under normal conditions ten times for 300 seconds. The same samples were tested ten additional times for 300 seconds after being vented and heated in an oven. In elemental analysis, samples are commonly swirled or tapped to create a more uniform sample. For this reason, each sample was heated, tapped lightly, and re-analyzed. The preparation process is shown in Figure 1.

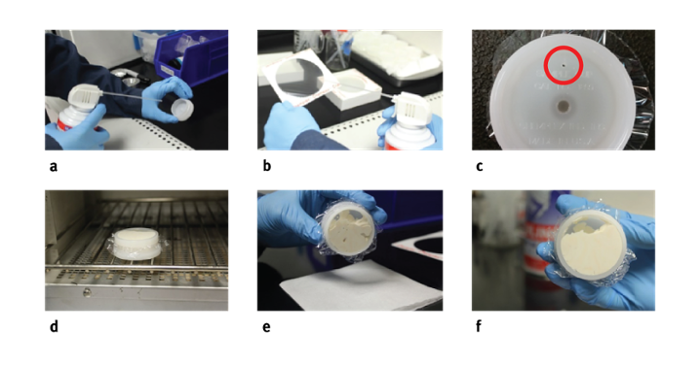

Figure 1: Sample Preparation

Compressed air is used to blow off any dust from an unused sample cup (a) and the grease is transferred into the cup. Compressed air is used to clean the sample film (b) and then placed over the cup and secured with a plastic ring to make a flat, tight surface. For heated tests, a venting hole (c) is created in the back of the cup and then the cup is placed in an oven (d) for 20 minutes at 40°C to lower the viscosity. For both heated and unheated tests, the sample is then held vertically (e) with the venting hole toward the top and tapped against a lint free towel until all the bubbles have been eliminated (f). The sample is now ready for measurement.

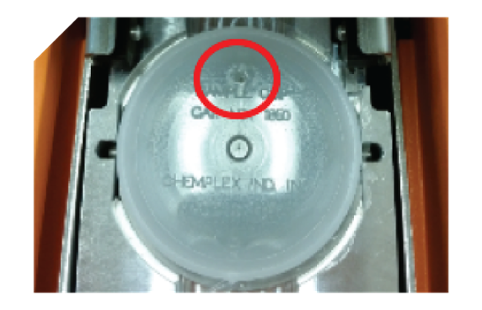

Figure 2: Petra MAX Sample Basket

For both heated and unheated sample measurements, the cup is inserted into the analyzer sample basket such that the bulk of the grease in the cup will not settle during the measurement as the cup is presented vertically to the measurement beam.

Note: The red circle highlights the proper positioning of the venting hole for heated samples to ensure the grease sample does not settle during measurement.

RESULTS

The data for heated samples versus non-heated samples outlined in Table 4 shows a slightly lower count across the board. While the sample counts should remain the same in the presence of heat, it is likely that some sample is burned off, which would cause a reduction in total and average counts.

| Table 4: Marine Calcium Greases | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ca (ppm) Non-Heated |

Ca (ppm) Heated |

P (ppm) Non-Heated |

P (ppm) Heated |

S (wt%) Non-Heated |

S (wt%) Heated |

Zn (ppm) Non-Heated |

Zn (ppm) Heated |

||

| Average | 57,400.7 | 57,437.0 | 3,506.3 | 3,198.2 | 0.6 | 0.6 | 20.6 | 20.5 | |

| Sample 1 | Std Dev | 24.4 | 84.6 | 58.6 | 88.3 | 0.0 | 0.0 | 0.2 | 0.1 |

| RSD | 0.04% | 0.15% | 1.67% | 2.76% | 0.27% | 0.34% | 0.8% | 0.46% | |

| Average | 57,958.8 | 47,812.1 | 3,456.4 | 2,087.1 | 0.6 | 0.4 | 20.4 | 17.8 | |

| Sample 2 | Std Dev | 33.2 | 785.8 | 63.6 | 91.0 | 0.0 | 0.0 | 200.1 | 0.2 |

| RSD | 0.06% | 1.64% | 1.84% | 4.36% | 0.47% | 4.66% | 0.36% | 1.32% | |

| Average | 57,775.0 | 55,975.5 | 3,705.7 | 3,327.3 | 0.6 | 0.6 | 20.2 | 20.1 | |

| Sample 3 | Std Dev | 36.8 | 739.5 | 61.6 | 216.5 | 0.0 | 0.0 | 0.1 | 0.2 |

| RSD | 0.10% | 1.32% | 1.70% | 6.51% | 0.40% | 2.95% | 0.50% | 1.07% | |

Lower grade greases typically have low counts for calcium, phosphorous, sulfur, and zinc, while higher grade greases tend to have high counts. Marine calcium greases are higher grade as they need to be water insoluble in order to work for their various applications. When measuring the lower-grade white lithium greases, we were unable to detect concentrations of any key elements, while marine calcium greases were all detected and reported in Table 4.

Both lubricant tests confirm that the relative standard deviation (RSD) is low enough to provide consistent results and enable trend lines to be observed as additives are depleted from use. As with the lubricant samples, low relative standard deviations (RSDs) are present across all grease sample data, which similarly indicates consistency in the method. Method consistency is vital for reliable analysis, as variability in the method can lead to off-specification product. With lubricants, keeping the final formulation in quality control relies on a highly precise quantification of elemental composition. In the petroleum industry, off specification product may result in fines and/or product downgrading, which can lead to millions of dollars in lost revenue.

CONCLUSION

Lubrication engineers and tribologists, as well as professionals in the petroleum industry utilizing greases and lubricants for practical use, place a high value on reliability when measuring for vital elements such as sulfur. With the consistency and precision of HDXRF technology utilized by professionals around the globe, those looking to measure their products for various elements can look no further than Petra MAX.

Footnote (1): When heating greases, it is possible to see lower concentrations. This is due to sample burn off which is possible depending on the type of grease sample measured. The heating source should not play a role in whether burn off occurs.

ADVANCED ANALYSIS WITH HDXRF

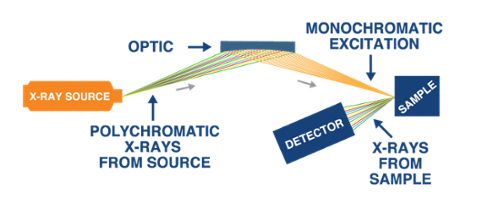

Petra MAX is powered by High Definition X-ray Fluorescence (HDXRF) technology: an elemental analysis technique offering significantly enhanced detection performance over traditional EDXRF technology. This technique applies state-of-the-art monochromating and focusing optics, enabling dramatically higher signal-to-background ratio compared to traditional polychromatic X-ray Fluorescence.

Figure 3 shows the basic configuration of HDXRF and its use of focused monochromatic excitation. In this system, the diffraction-based doubly curved crystal optics capture a wide angle of X-rays from the source and focus a narrow energy band (monochromatic) of X-rays to a small spot on a measurement cell. The monochromatic beam excites the sample and secondary characteristic fluorescence X-rays are emitted. A detector processes those secondary X-rays and the instrument reports elemental composition of the sample.

Figure 3: HDXRF Diagram

Petra MAX

Petra MAX delivers advanced D4294 sulfur analysis in addition to 12 elements from P to Zn including Ni, V, and Fe. This robust benchtop analyzer complies with ASTM D4294 and ISO 8754 for measuring sulfur in hydrocarbons. Petra MAX is powered by HDXRF, utilizing XOS patented doubly curved crystal optics coupled with a high-performance silicon drift detector and an intense monochromatic excitation beam. This industry-leading technology reduces background noise and increases signal-to-noise output, enabling low detection limits and high precision without the need for consumable helium gas, a vacuum pump, or extensive sample preparation.

Author: Joseph Iaia, Petroleum Product Manager