- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Real-Time Total Chlorine Monitoring to Ensure Optimal Desalter Performance

Abstract

Chlorides are always present in raw crude oils and their concentrations vary greatly. Depending on origin, transportation methods, and process conditions, chloride concentrations can spike in a very short period and lead to devastating corrosion events across the refinery. Some estimate that global corrosion damage is around 15 billion USD annually, and this doesn’t take into account the profit and production time loss. There are a variety of factors that contribute to this corrosion, and it is of the utmost importance to have as much data for as many parameters as possible to effectively combat corrosion before it can cause serious problems. XOS’ Clora® Online, X-ray fluorescence industrial process analyzer, provides a total chlorine measurement in real-time for use in desalter management and corrosion reduction plans.

Background

When present in the furnaces of atmospheric and vacuum distillation units, NaCl, MgCl 2, and CaCl 2 will hydrolyze to form hydrogen chloride vapors. When these vapors mix with condensed water in the cooler sections of the tower, they form highly corrosive hydrochloric acid. This leads to serious corrosion events and turnarounds, or worst case, fires and explosions. Chlorides that don’t hydrolyze can lead to fouling, heat exchanger efficiency loss, and extreme local corrosion which decreases the life span of the heat exchanger.

The crude desalter is the first line of defense and a critical piece of equipment tasked with removing chlorides by dilution, emulsification, and coalescence. Ideally, the desalter achieves 90% removal efficiency, and even with second stage desalters, the chloride removal is at best 99%. However, during upsets, far more chlorides can pass through and enter the atmospheric tower. This can lead to catastrophic corrosion damage if not detected.

There is a direct correlation between unit life and desalter performance. Changing crude slates makes effective desalting more difficult due to the variable crude quality and unintended side effects of incompatible blends. This in turn leads to higher and variable desalted crude salt content, further affecting unit reliability. In addition, the optimal desalter operating conditions are not static values, and real-time changes must be made to reduce risk to the atmospheric tower and other valuable units.

The vast majority of chlorides entering the desalter are inorganic chlorides of the sodium, magnesium, and calcium variety and will mostly be removed through proper desalter operation. Some chlorides, termed nonextractable chlorides, cannot be removed by the desalter and end up in the atmospheric or vacuum distillation units, or naphtha hydrotreater units. There is not one location that these originate from, but they are typically either organic in nature or inorganic chlorides enshrouded in paraffins or asphaltenes.

In events where organic chlorides make it to the naphtha hydrotreater, they can be subjected to conditions whereby they form HCl. Under normal conditions, NH 3 generated from the denitrification process in the presence of HCl form dry NH 4Cl salts which can deposit on the heat exchangers. While these dry salts are not corrosive, they are extremely hygroscopic, and in the presence of water can lead to extreme local corrosion issues. The deposits on the heat exchangers are typically removed by periodic injections of neutralized wash water. An effective chloride measurement is critical here as a ratio of nitrogen to organic chloride in the feed dictates the necessity of either periodic or continuous water washing. The neutralization required by this wash water is also determined by the measured chloride content.

Temperature adjustments of up to 25° C may be necessary to avoid asphaltene precipitation and allow for the removal of formerly non-extractable chlorides. Organic chlorides have been found to originate from chemical cleaning solvents used in the production fields. Such solvents have historically also been used to clean industrial equipment to dissolve deposits composed of waxes, paraffins, and tar. Finally, chloride-based solvents used in fracturing fluids have been used for well stimulation. If these solvents contaminate the crude oil, they are typically oleophilic, meaning they do not easily separate from crude oil, and rarely get removed in the desalter. To make matters worse, at low levels these chlorides will not be detected by most analytical techniques, and most salt in crude analytical techniques will not measure them at all. Therefore, refiners are unaware of their presence even with a good monitoring program.

In one case, a refinery had as little as 1% of the nonextractable chlorides hydrolyzing in the atmospheric distillation unit, which led to new overhead condenser tubes failing in less than 14 hours. In another case, non-extractable chlorides that made it to the naphtha hydrotreater reduced the service life of the heat exchangers to 33 days.1 While these are extreme cases likely caused by poor material selection choices, chlorine corrosion can still cause failures in as little as a few months in installations where appropriate materials are used.

A variety of methods to deal with unit corrosion have been used, such as source control, crude blending, monitoring of the overhead and use of neutralizer, monitoring of the crude and use of caustic, and other chemical additions. In extreme cases, some refiners upgraded metallurgy in all condensers and associated piping at great cost. These responses may be appropriate for normal operation but will not be adequate for upset conditions or for different crude slates.

Occasionally, more problems develop in an attempt to solve corrosion issues. For example, use of too much caustic can lead to fouling and stress corrosion cracking in the coker unit. A proper monitoring schedule is critical to develop and maintain effective corrosion reduction plans.

Typical chloride inspection occurs by grab samples and lab measurement as little as once a week. While these measurements may look good and indicate proper performance, they usually miss potentially catastrophic chloride spikes. Industry leader Nalco Champion has conducted studies that show 90% of corrosion damage occurs in as little as 10% of the time. These spikes occur during crude tank switches, slop oil processing, processing of opportunity crudes, and other unstable periods of operation. Untreated, these spikes cause the greatest amount of corrosion damage over the unit’s lifetime. In addition, many measurement techniques and lab protocols fail to take sample settling into account, leading to a misleading measurement. Process control based on this type of monitoring program is impossible.

The key to effective corrosion control begins with an effective chloride measurement regimen. By knowing the desalter inlet and outlet crude, as well as overhead chloride content, changes can be made to optimize the desalter in real-time. The ability to track the effects of other changes, such as caustic injection in the desalted crude, neutralizer in the overhead, or institution of a water wash, enables the most effective corrosion mitigation program. By monitoring the naphtha hydrotreater chlorides, process control is enabled and catastrophic corrosion events can be prevented. Online chloride monitoring helps to optimize a plant’s profit, performance, and safety.

Introduction

Over the last 20 years, XOS has proven itself as a leader in online sulfur analysis using Monochromatic Wavelength Dispersive X-ray Fluorescence (MWDXRF®) technology with over 250 analyzers in refineries worldwide. Initially, online chlorine analysis in crude presented more challenges due to low-level quantification requirements and sampling complications. Typical measurement techniques that involve separating the oil from water, mixing, and measuring have traditionally run into problems where chlorides settle out of solution leading to different measurements over time. In addition to this, limited testing frequency and extended time between when the sample was grabbed and when it was measured often make these measurements useless in upset identification and control. To this end, a MWDXRF chlorine in crude analyzer was developed.

Introduced in 2007, Clora benchtop analyzers have been adopted by over 100 refineries as a part of their chlorine monitoring and corrosion mitigation strategies. While these analyzers allowed far more sample types to be analyzed, they ran into many of the same sampling issues previously experienced. In 2010, Clora Accuflow was released to take chloride settling into account. However, this did not change limited sampling frequency or the time to get the sample to the lab for analysis. In 2011, Clora was adapted for an online solution and has since been used to measure crude and water samples globally. Clora Online uses the same proven technology combined with XOS’ years of experience in process analysis and is capable of measuring from 0.2 to 3000 ppmw total chlorine in hydrocarbon and aqueous samples. (Aqueous LOD 0.5 ppmw)

Methods & Materials

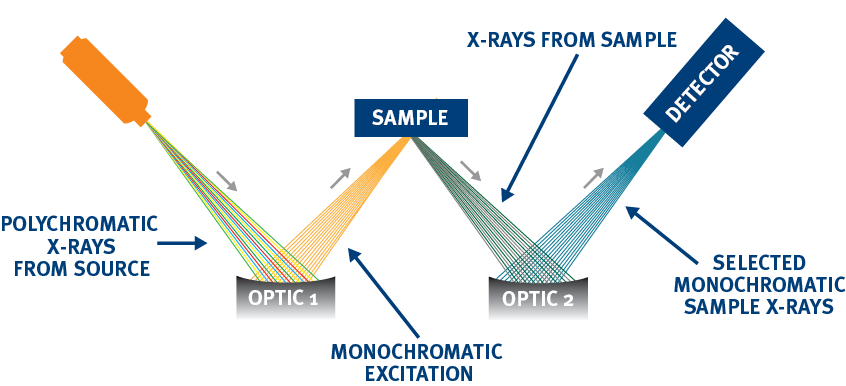

The analyzer consists of a low-power X-ray tube, an X-ray focusing chamber with both focusing and collection optics, a dynamic window module sample cell, and a detector as depicted in Figure 1.

MWDXRF utilizes focusing and monochromating optics to increase excitation intensity and dramatically improve signal-to-background ratio compared to traditional WDXRF instruments. This enables significantly improved detection limits, precision, and a reduced sensitivity to matrix effects.

Figure 1: MWDXRF Diagram

X-rays are generated in a low-power X-ray tube in a lead shielded engine. These polychromatic X-rays (spectrum of wavelengths) are monochromated (a single wavelength is selected) and focused using a state-of-the-art doubly curved crystal optic. The focal point is aligned to be just on the other side of an X-ray transparent polyimide film sealing the sample chamber. These X-rays interact and excite chlorine atoms which fluoresce characteristic X-rays. These X-rays are collected, monochromated, focused onto a detector, and are then registered as “counts”. Sample continuously flows through the sample cell during this process, and the measurement can be made in as little as 15 seconds. The sample never enters the cabinet, thus protecting sensitive electronics and optics. This method does not require consumable gasses or sample conversion, and due to the nondestructive nature, sample can be returned to an appropriate low-pressure return. The collection time is selected based on a required response time and precision. The number of X-rays are converted to ppmw by a calibration curve linear from 0.2-3000 ppmw. This number is displayed on a HMI (human machine interface) and communicated via a 4-20 analog output, or optional Modbus TCP, 232, or 485.

In order to maintain a consistent and stable measurement and to avoid drift, the sample will periodically be purged using N 2 or instrument air and the polyimide film will “advance” on a reel-to-reel assembly. This automated process takes about 90 seconds and is typically done every 6 hours, depending on sample conditions. During this process, the system checks itself for leaks and drifts in calibration. Automatic validations can also be scheduled. To allow flow of more viscous materials, the analyzer can run samples up to 160 cSt at sample temperatures up to 135° C. To limit filter replacement frequency, only a 100-μm front-end filter is required. An intense monochromatic beam coupled with a highly efficient collection optic allows for superior rapid detection capabilities to identify and accurately report transients, as well as verify stable operations.

Application Study

Several online chlorine analyzers were used to collect sample data and demonstrate LOD, precision, and response time. A sample circulation system was designed to allow continuous flow through the analyzer of 8 gph for multiple days of testing. Each analyzer’s film advance interval was set to 4 hours, and the signal integration time was set to 300 seconds.

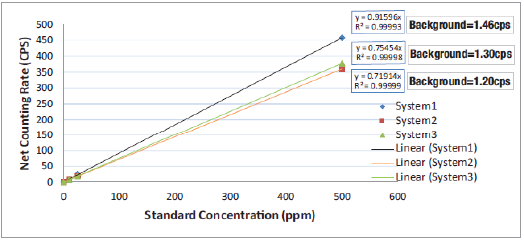

Each analyzer had a new X-beam/engine aligned, and each system operated at 50 kV and 1.0-1.2 mA. Each unit was calibrated using xylene-based chlorine standards (further testing determined a synthetic diesel fuel matrix to be the best calibration standard for hydrocarbon sample streams. De-ionized water is suitable as a matrix for aqueous streams). The concentrations used were 0, 10, 25, and 500 ppmw. Each sample was introduced to the sample cell and held static and pressurized for 300 seconds. The three calibration curves were linear up to the 500 ppmw (and in fact are linear up to 3000 ppmw) with a 0.9999 R 2 value as seen in Figure 2. The difference between calibration curve slopes can be attributed to slight variations in the alignment procedure for each engine. The engine current can be adjusted to ensure performance parameters are achieved.

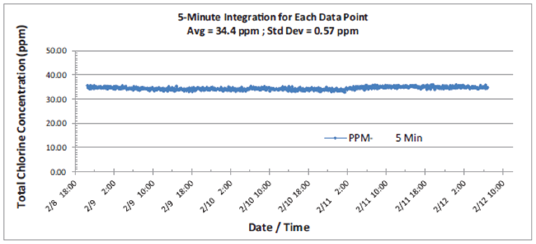

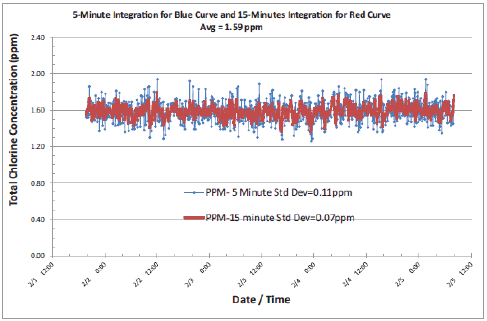

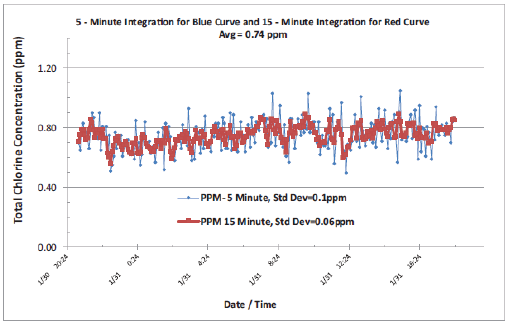

Raw and desalted crudes obtained from refineries for this study were run between 21 and 84 hours to demonstrate stability and repeatability as seen in Figure 3 and Figure 4.

Figure 2: Calibration Curves For 3 Clora Online Analyzers

Figure 3: Measuring Western Canadian Raw Crude with Clora Online over 84 Hours

Figure 4: Measuring Western Canadian Desalted Crude with Clora Online over 84 Hours

Figure 5 depicts an additional sample of mineral spirits run through the analyzer for 21 hours showing a standard deviation of 0.1 ppm using 5-minute integration times. The standard deviation dropped to 0.06 ppm when using 15-minute integration times demonstrating the effect of counting time on precision.

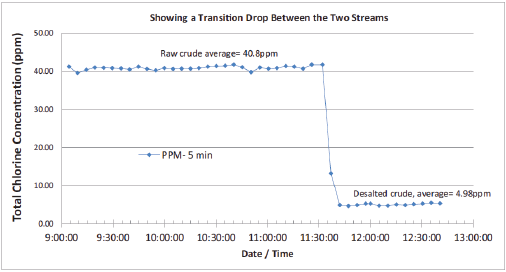

Two containers, one containing raw crude and the other desalted crude, were connected to the sample circulation system. The sample could be chosen via three-way valves. The raw crude was pumped to the measurement cell for the first 2.5 hours with 5-minute measurement intervals. The sample was then switched to the desalted crude for 1 hour. As seen in Figure 6, the concentration drops from 41 ppm to 4.8 ppm in two transitions with no tail in the integration time, indicating no memory or residue effect from the high-concentration raw crude stream.

Figure 5: Measuring Mineral Spirits with Clora Online Over 21 Hours

Figure 6: Raw Crude to Desalted Crude Switch with Clora Online

Case Study

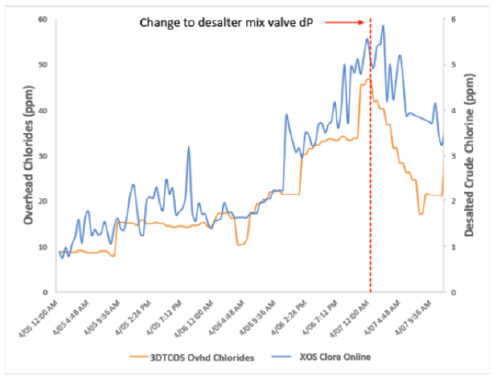

Clora Online was installed at a gulf coast refiner on desalted crude by Nalco Champion to provide unprecedented desalter analysis and control in conjunction with their 3DT COS overhead water analyzer. While in operation, Clora detected both inorganic and organic chlorine in real-time, allowing upsets to be identified and quick responses to mitigate risks.

Shortly after being installed, the desalter feed rates had to be reduced due to a local operational problem. Clora Online reported a climb in chlorides exiting the desalter, confirmed by the Nalco 3DT COS on the overhead as seen in Figure 7. This climb was attributed to a decreased mix valve dP, reducing mixing efficiency and leading to poor desalting performance. Neutralizer dose rates were increased to ensure satisfactory overhead sour water pH, and the mix valve dP was increased back to typical operating levels. Clora Online registered a decrease in chlorides almost immediately.

Figure 7: Upset Identified in a Large Gulf Coast Refinery

Conclusion

Clora Online not only provides an effective tool for salt content monitoring, but also serves as an important process control tool for chlorine content in desalted crude and other process streams further downstream in the refinery process. By using Clora in addition to the Nalco CrudeFlex program, refiners can rest assured they are getting the most out of their desalter, thus reducing corrosion, maximizing profit, and making sure everyone gets home safely at the end of the day.

XOS has partnered with Nalco Champion, and Clora Online is now an important asset in their CrudeFlex monitoring and desalter management program.

With ever-changing crude quality and blends, chlorine levels can shift quickly, making real-time analytical results invaluable. Clora® Online delivers real-time, continuous analysis of total chlorine from 0.2 ppmw up to 3000 ppmw. By monitoring desalted crude, a plant can optimize performance and immediately see impacts of crude changes (including organic chloride). Powered by MWDXRF®, Clora Online uses ASTM D7536 technology and is ATEX and NEC certified.

3D CRUDEFLEX TECHNOLOGY BY NALCO CHAMPION, AN ECOLAB COMPANY

In challenging environments, refiners should not have to compromise potential opportunities vs risk. 3D CrudeFlex technology consists of a suite of online stream analyzers that provide an enhanced level of system assurance by mitigating process upsets before they escalate and considerable damage occurs. This increased level of insight enables refiners to proactively manage crude unit threats and allows safe processing of a more opportunistic crude slate.

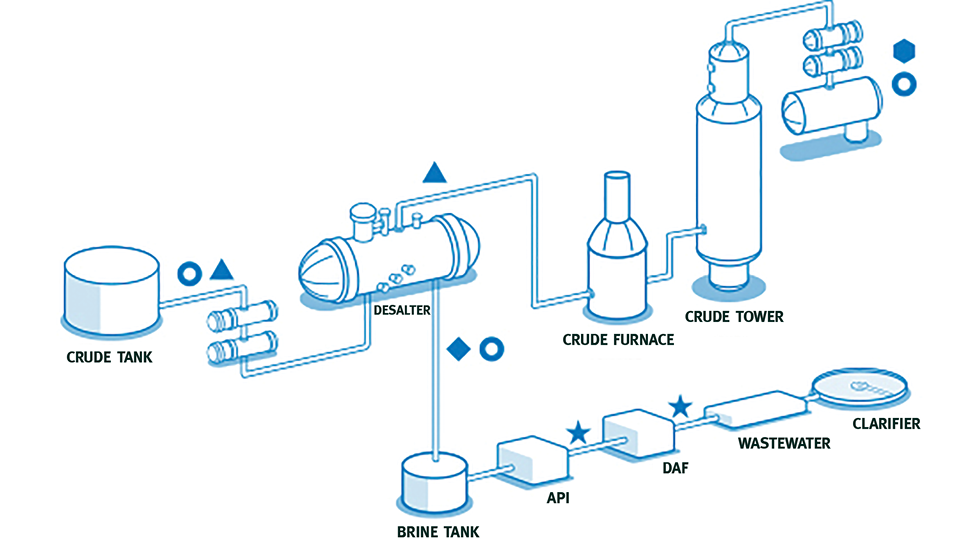

Clora Online is a key piece of 3D CrudeFlex as the online salt analyzer, allowing for real-time desalter optimization. A total system approach is needed to optimize the desalter, which requires the adjustment of the mechanical, operational, and chemical aspects of the unit. Typical optimization of the desalting parameters like level, mix valve, wash water rates, chemical addition, etc., can be a time-consuming process, given the time it takes for the changes to take effect on the unit.

By installing the 3D CrudeFlex Online Salt Analyzer, optimization can occur in a near real-time manner while also ensuring that ongoing desalter performance meets critical KPIs, upsets can be detected quickly and mitigating actions can be taken. The 3D CrudeFlex Online Salt Analyzer can be used to sample the inlet and outlet of the desalter, thereby providing a continuous reading of total chlorine in the crude oil. Both inorganic and organic chlorine are detected with continuous real-time chlorine measurements, and optimization of the key operating variables allows for the lowest possible salt levels to be achieved in the desalted crude. Keeping low salt levels in the desalted crude stream can significantly reduce the risk of costly corrosion in distillation overhead systems throughout the refinery complex.

Clora Online is represented by the solid triangle in this 3D CrudeFlex diagram.

References

1. Effect of Nonextractable Chlorides on Refinery Corrosion and Fouling, NACE

Author:

Evan Thomas, Business Manager – Process Analyzers