- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Clora 2XP: Accurate Chlorine Measurement for Advanced Plastic Recycling

Tiobesta Feleke

Clora 2XP: Accurate Chlorine Measurement for Advanced Plastic Recycling

Tiobesta Feleke

Tiobesta Feleke

The issue of plastic waste and its environmental impact continues to escalate globally; however, scientists believe that an effective way to reduce global plastic waste could be through recycling. There are two main types of recycling waste polymer streams: mechanical and chemical recycling. These two types are no longer discrete processes, as both involve physically processing plastic materials to create new products. However, chemical recycling involves different technologies for breaking down polymers, such as pyrolysis, gasification, hydro-cracking and depolymerization. These building blocks can then be used to make new products.

When it comes to recycling, there are three methods: mixing different plastics for fuel conversion, focusing on a single plastic type, and physically processing plastic materials to create new products.

Let's explore these methods.

In this method, various types of plastics are combined and processed to produce fuels such as diesel or gasoline through a chemical conversion process. This approach aims to utilize the energy content of plastics that are otherwise challenging to recycle conventionally.

Here, the emphasis is on recycling a specific type of plastic, such as PET or polyethylene, by breaking it down into its chemical components. By isolating and purifying the material, it can be used to manufacture new products, reducing the need for virgin plastics and mitigating environmental impact.

This method involves mechanically treating plastic waste to transform it into raw materials suitable for producing new products. Through processes like shredding, melting, and molding, the plastic is reformed into items ranging from packaging materials to construction components, promoting circularity in the plastic economy.

While these methods offer promising avenues for tackling plastic waste, challenges persist in the recycling process, particularly concerning the presence of chlorine-containing materials like PVC. This contamination can disrupt equipment functionality, leading to costly maintenance and safety hazards. Consequently, innovative solutions are essential to address such issues and enhance the efficiency of plastic recycling processes. Among these solutions, precise measurement tools like XOS' Clora 2XP play a crucial role in ensuring the quality and integrity of recycled materials.

Chlorine-containing materials, such as PVC, can contaminate the recycling process, causing processing equipment corrosion, a critical and very expensive problem. Plastic recyclers have found that screening for and reducing chloride contamination can significantly increase the time between turnarounds, lower costs of corrosion, and decrease related safety hazards; therefore, measuring chlorine is imperative in this process.

XOS’ Clora 2XP, with its automatic sulfur correction capability, can measure low-level chlorine accurately using modified ASTM D7536 methodology.

For this application, Clora 2XP was calibrated with a chlorine in a mineral oil calibration standard set that included the following data points: 0, 0.5, 1, 2, 5, and 10 ppm chlorine. The methodology is based on a modified ASTM D7536 procedure, which involves measuring three unique chemically recycled naphthas and three unique chemically recycled gas oils instead of aromatic samples and using a mineral oil calibration instead of a p-xylene calibration.

Related: Prevent disruption to the plastic pyrolysis process

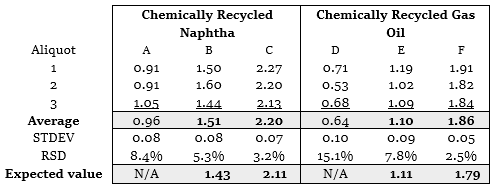

A major North American plastic recycler prepared six samples: four of them were doped, and the other two were undoped. These samples were then sent for analysis as unknowns. Each sample was measured on Clora 2XP three times for 300 seconds (new aliquot for each repeat) using automatic sulfur correction. (See bold values in Table 1 for average measurement results and the expected values.)

In each case, Clora 2XP demonstrated excellent accuracy and precision in line with the expected values provided by the plastic recycler.

Without correcting for sulfur during XRF sample analysis, secondary excitation of sulfur by the chlorine fluorescence will lead to biased results. Clora 2XP has an automatic sulfur-correcting feature that can be enabled during measurement. Fortunately, automatic correction does not require a known sulfur content as the sulfur concentration is measured concurrently with chlorine.

The result of this application study demonstrates that Clora 2XP, with its automatic sulfur correction and sub-ppm LOD capabilities, is an ideal solution for measuring low-level chlorine in the advanced plastics recycling industry, especially when the sample contains high levels of sulfur. This simple measurement requires just a few minutes to complete and requires no consumable gases or chemicals.

Effectively monitoring chlorine concentration in plastics recycling is a critical part of the corrosion mitigation strategy, but also contributes to efforts to improve reliability and product quality. With the capability to quantify chlorine at sub-ppm levels in hydrocarbon samples, processors can reduce the risk of extensive costs of corrosion and processing inefficiencies.

Easier to use than ever, Clora 2XP analyzes total chlorine in liquid hydrocarbons such as aromatics, distillates, heavy fuels, and crude oils, as well as aqueous solutions, while automatically correcting for sulfur interference.

The enhanced precision and performance technology makes it the ideal choice for testing related to catalyst poisoning in reformers or for sites with fluid catalytic crackers and hydrocrackers monitoring very low chlorine levels.